The Importance of Wood Grain Direction in Shed Durability

Woodworkers often speak about grain in relation to milling, or making sure a joint remains aligned properly in response to environmental fluctuations; reading and understanding grain is integral for any successful woodworking experience.

Grain tells a tale, impacting strength, stability, and workability of wood. Understanding these natural variations helps builders plan and construct projects with longevity in mind.

Strength

Wood grain is one of the cornerstones of woodworking; it affects everything from strength and stability, appearance and workability of lumber pieces, carving and milling projects, shed construction, as well as durability considerations. Understanding wood grain is therefore essential to success when undertaking any carving or milling projects or other woodworking activities that involve carving or milling processes; additionally it has an important place in durability considerations for wooden structures like sheds.

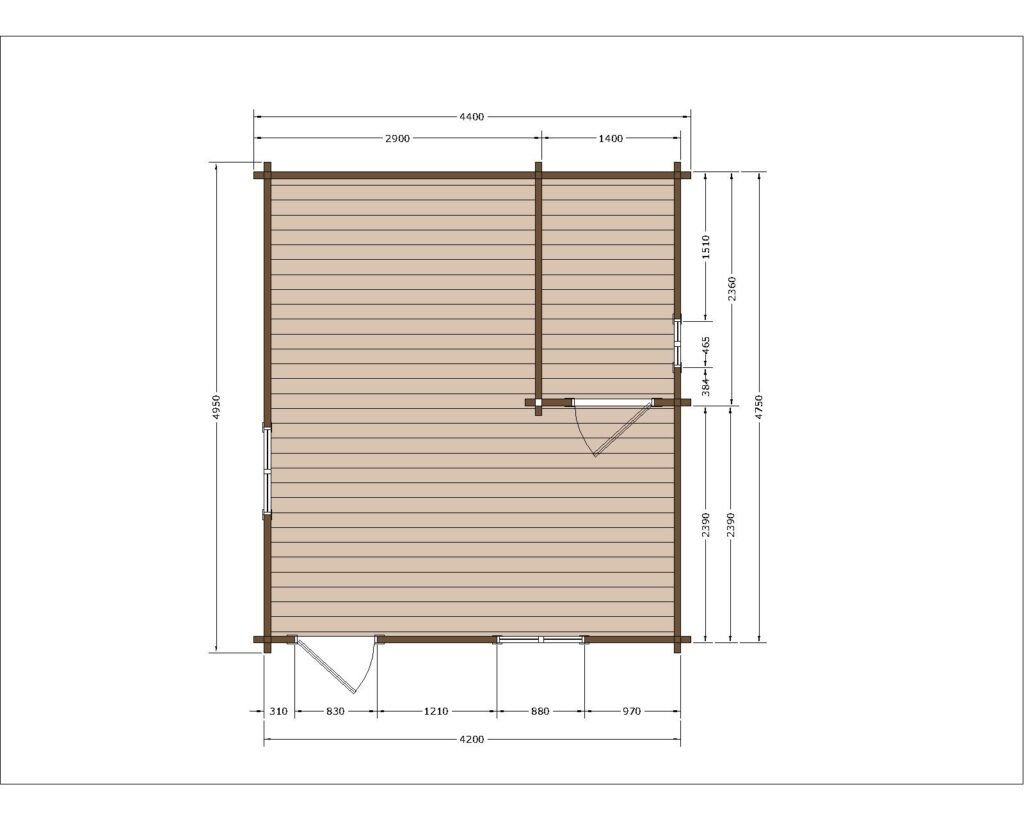

Just like with any building, sheds’ true strength lies in their foundation. A good one usually comprises at least 4-inches thick reinforced concrete slab that extends 2-3 inches beyond all sides of the shed dimensions – typically 4-inchs thick – this extra expense upfront has proven invaluable by keeping soil moisture away and creating an even surface; experts also advise sizing your shed to accommodate future storage needs – overfilling can make maintenance challenging, potentially leading to structural damage.

When shopping for a wooden shed, be sure to consider one that has been treated with pressure-treated wood to infuse preservatives deep into its fibers and protect them from rot, fungal decay and insect damage. A quality shed should also be placed slightly elevated above its gravel base to allow proper drainage – standing water around its base can accelerate corrosion of lower panels and floor framing and pose potential threats.

Durable outdoor sheds crafted from multi-wall resin are quickly revolutionizing the storage market. These modern marvels boast high impact resistance and load bearing capacities of solid-steel structures without their weight and expense. Furthermore, many premium resin models include double or even triple wall panels along with steel reinforcement at key stress points to deliver exceptional strength – capable of withstanding substantial snow loads, for instance.

An excellent and durable shed requires only minimal upkeep for optimal performance. Repainting it regularly with quality acrylic latex exterior paints helps minimize wear and tear and prolong its life; inspecting and tightening fasteners annually prevents minor issues from becoming structural issues; while placing the shed on an elevated foundation and using appropriate size can help avoid moisture infiltration and deterioration.

Moisture Movement

Woodworkers depend on an in-depth knowledge of wood grain to create works of beauty that stand the test of time. Grain refers to the direction in which longitudinal cell fibers grow, an aspect that affects strength, stability, workability, as well as producing distinct patterns such as curl, quilting, mottle or blistering in woodworking projects.

Grain differs from texture, which refers to the relative sizes and distributions of cells within boards or pieces of lumber. While woodworkers often refer to this characteristic by calling it „grain,” when assessing strength it would be more accurate to look at texture instead.

Hygroscopic properties of wood allow it to absorb and release moisture as air temperatures fluctuate, making air or kiln drying wood to an MC of 9-14% ideal for building shed walls and roof structures; however, this process cannot always ensure an even distribution of moisture throughout each lumber piece.

Shed ventilation is an integral component of mitigating humidity fluctuations that can damage building materials over time. Too high humidity levels cause wood to swell and shrink, weakening support beams and warping in walls and roof structures; too low of humidity levels allows mold spores to flourish while corrosion damages metal components.

Regular shed ventilation helps balance humidity levels, lowering the risk of moisture damage to building materials and prolonging their longevity. This is particularly important during seasonal changes when temperature and humidity can fluctuate greatly from winter to summer. An airy shed helps ensure an even distribution of temperature and moisture, decreasing the risk of localized damage like rot or mildew growth. Shed ventilation also prevents excess moisture from collecting in tools, garden supplies and furniture stored inside, thus lowering the risk of mold and mildew growth and helping protect metal tools from rusting as well as woodwork projects from being compromised by swelling boards. Therefore it’s crucial that sufficient ventilation be present all year round, and regular tasks like vent cleaning be part of your Spring shed maintenance regimen.

Warping

Woodworkers rarely discuss wood without discussing „grain.” This essential characteristic affects every aspect of its workability and appearance – from strength and stability to how the grain reacts with moisture – thus making understanding its significance key for successful craftsmanship and building projects.

Grain refers to the arrangement of longitudinal cells within wood pieces that reflect how trees grew. When under stress, pressure is better distributed when applied parallel to the grain reducing risk of breakage and increasing strength and durability of structural pieces such as beams and table legs with consistent graining for maximum strength and endurance.

Grain direction also affects how wood reacts with moisture changes. When humidity levels fluctuate, wood expands and contracts more across than along its grain, potentially leading to warping or twisting that reduces strength and stability. To mitigate this issue, structural pieces should generally have their grain running lengthwise to maximize strength and stability.

Wood grain patterns can produce distinct visual characteristics. Ribbon stripe figures, for instance, can be created by trees with interlocked grains that spiral in one direction for several years before switching back out again – an effect common among tropical species like sapele and bubinga. Though visually striking, ribbon stripe figures can be difficult to work with as they’re more susceptible to tear out when milled or machined.

Woodworkers quickly learn to read a piece of wood’s grain and adjust their techniques and tooling accordingly to achieve the desired result. For example, when planing wood you need a grain direction that rises in front of your hand tool or cutter head – this helps avoid tear-out and ensure superior results.

Understanding wood grain is especially crucial when it comes to finishing and staining projects made with open or closed grain wood pieces, as matching its stain or finish color with its appearance will undermine its aesthetic value and impact negatively upon your project’s final look.

Cracking

Wood grain is more than merely aesthetic; it impacts how materials behave under pressure and humidity changes. A woodworker who understands grain structure and direction can use their knowledge of it to ensure longevity for their finished products by preventing structural failures as well as inform design and construction methods to maximize each piece of lumber available to them.

Wood’s orientation plays a huge role in how tools interact with it; cutting, chiseling and routing wood along its grain produces better results than working against it which may result in tearout or other defects. Experienced woodworkers quickly learn to „read” the grain and adjust their techniques accordingly.

Understanding grain direction is especially crucial for sheds with interior storage as moisture can become an immense problem. Moisture trapped within a shed can corrode metal equipment, cause wooden tools to warp and expand, promote mold growth and mildew growth and lead to mold and mildew buildup – but with proper ventilation in place, moisture can escape and help extend its useful life of both materials and structures within.

Moisture movement also poses a threat to sheds’ ability to maintain their shape and stability over time, as it’s more likely for it to shrink or expand across its grain rather than along it. This shift may result in cracked joints, loose binders or drawers no longer holding their contents securely – so carefully considering these changes when designing and building can prevent your shed from succumbing over time.

Quality materials used in shed construction and materials are also vitally important to its long-term durability. Sheds with higher-grade construction and materials tend to be less susceptible to fading, cracking, or breaking than those made from lower-grade plastics; vinyl sheds for instance tend to be more resilient against extreme temperatures and sunlight than plastic sheds that lack insulation and ventilation; proper ventilation allows airflow through sheds that collect damp air which reduces mold growth risk.